Empowering Petroleum Excellence

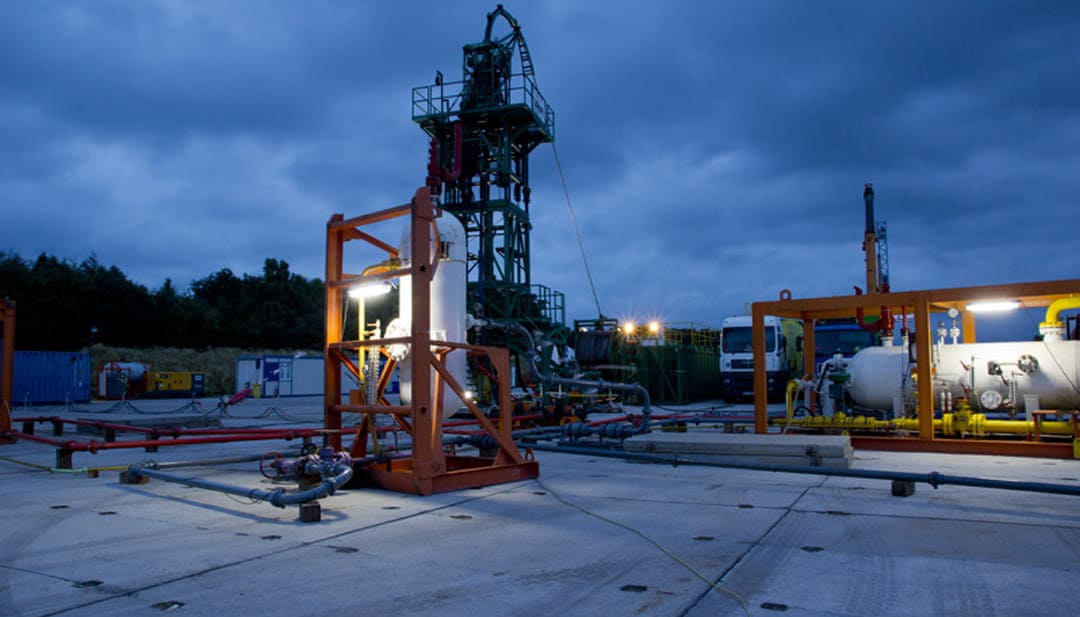

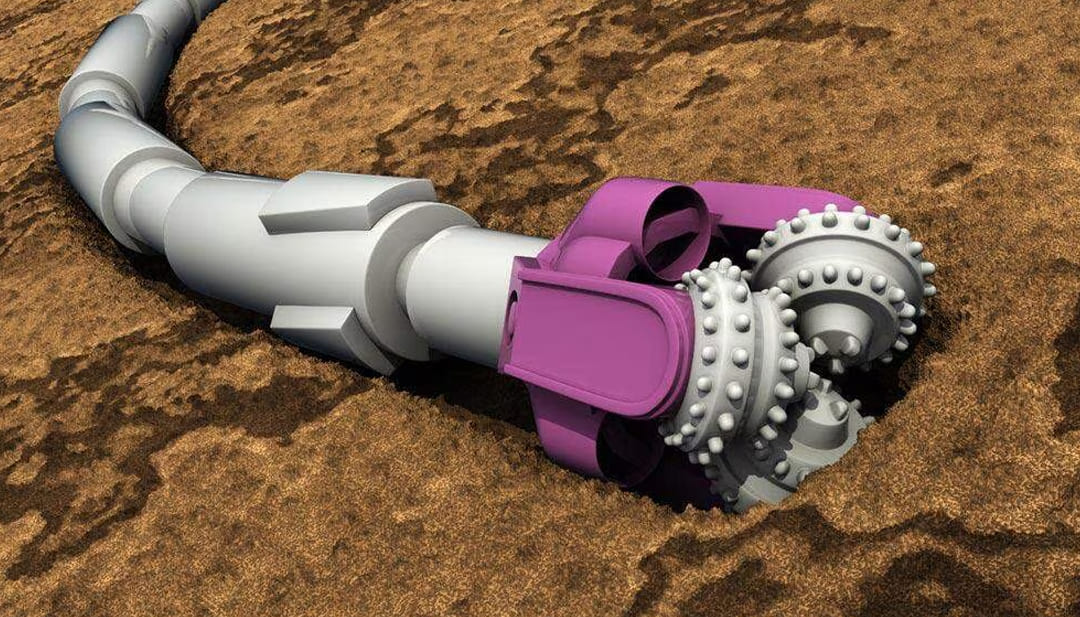

Explore TamCapital, a trusted name in the petroleum industry, delivering innovative solutions and comprehensive services across drilling, well services, and cutting-edge technologies. Discover how we redefine industry standards with a commitment to quality, sustainability, and excellence.